HOWO Special Truck Co., Ltd. is one of China’s leading commercial vehicle dealers, specializing in the sale of high-quality HOWO tractor series. These tractors are renowned for their exceptional performance and reliability, widely used in long-distance freight and heavy-duty transportation. Maintaining the braking system of HOWO tractors is crucial for ensuring safety and optimal performance. Regular maintenance ensures the braking system performs excellently under various road and working conditions, providing safe and reliable hauling solutions through continuous innovation and technological advancements.

Table of Contents

HOWO Tractors

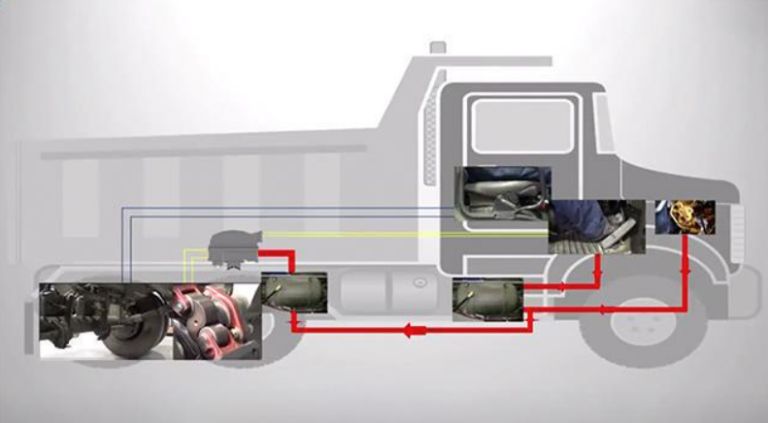

Introduced by China National Heavy Duty Truck Group, HOWO tractors are high-performance commercial vehicles known for their reliability and powerful engines. Equipped with a variety of engine models ranging from 240 to 420 horsepower, these trucks are widely used for long-distance freight and heavy-duty transportation, such as towing trailers and semi-trailers. HOWO tractors are designed with a focus on comfort and safety, featuring advanced driver assistance systems and comfortable cabins.

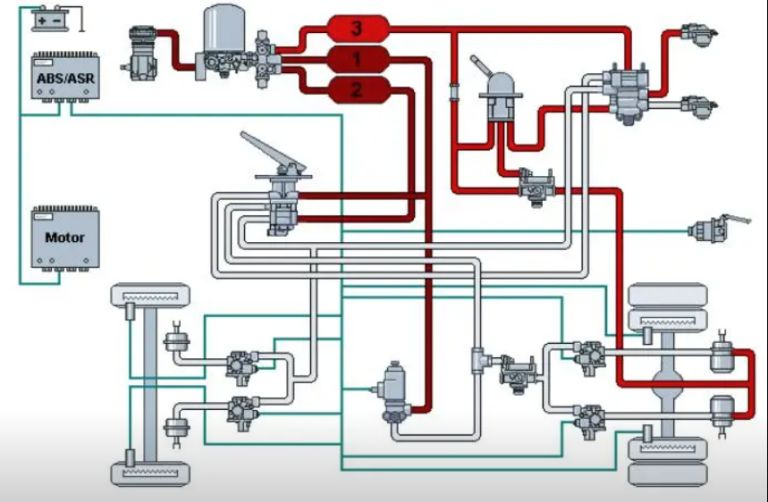

A well-maintained braking system is essential for commercial trucks. The proper functioning of the braking system directly affects the vehicle’s safety and operational efficiency. HOWO tractors utilize advanced braking technologies, such as Anti-lock Braking System (ABS) and Electronic Brake-force Distribution (EBD), ensuring stable braking performance under various road and load conditions. Regular inspections and maintenance of the braking system, including replacing brake discs and pads and cleaning and adjusting the hydraulic braking system, are key steps to ensuring long-term vehicle operation and safe transportation.

Importance of Regular Brake Maintenance

Regular maintenance of the braking system is critical for vehicle safety. The braking system is a key component of driving safety, and regular maintenance can significantly reduce the risk of accidents.

Ensuring Optimal Braking Performance: Over time, brake pads and discs wear out due to friction, leading to reduced braking efficiency. Regularly inspecting and replacing severely worn brake pads and discs can ensure stable and reliable braking performance, reducing the risk of accidents caused by brake failure.

Consequences of Neglecting Brake Maintenance: Ignoring brake maintenance can lead to increased braking distances, putting the driver at higher risk in emergency situations. Severely worn brake pads increase the time required for the vehicle to come to a complete stop, which is crucial in avoiding collisions. Additionally, brake system failures, such as brake fluid leaks, can lead to serious traffic accidents, posing a threat to the driver and other road users.

Benefits of Maintaining an Optimal Braking System: Maintaining an optimal braking system not only enhances safety but also improves the driving experience and extends the vehicle’s lifespan. A good braking system can respond more effectively to the driver’s commands, enhancing overall driving performance and reducing the additional wear on other components, thus extending the lifespan of the entire vehicle.

Checking Brake Pads and Discs

How to Check Brake Pads and Discs for Wear:

- Regularly inspect the thickness of brake pads and discs. If the brake pad thickness is too low or the disc surface has noticeable grooves, they should be replaced promptly.

- Use a brake pad thickness gauge to check the thickness of the brake pads and ensure they are within the safe range.

- Check the brake disc surface for flatness, cracks, or severe wear.

Signs of Worn Brake Pads and When to Replace Them:

- If the brake pad thickness is below the manufacturer’s recommended minimum, they should be replaced immediately.

- If there is a sharp metal grinding sound when braking, it could indicate the brake pads have worn to their limit, with the metal backing plate contacting the brake disc.

- Noticeable reduction in braking performance and increased braking distances are also signals that the brake pads need replacement.

Importance of Using High-Quality Brake Pads and Discs:

- High-quality brake pads and discs offer longer service life and more stable braking performance.

- Low-quality brake components can lead to poor braking effect and increased accident risk.

- Choose original or well-known brand brake pads and discs to ensure they meet the vehicle manufacturer’s specifications and requirements.

Checking and Replacing Brake Fluid

How to Check Brake Fluid Levels and Its Importance

Checking Brake Fluid Levels:

- Open the hood and locate the brake fluid reservoir, usually near the master brake cylinder.

- Check the fluid level markings on the reservoir and ensure the brake fluid level is between the “High” and “Low” marks. If the level is below the “Low” mark, add brake fluid.

- Ensure the brake fluid is clear or light yellow. If the fluid is dark, it may need to be replaced.

Importance of Brake Fluid:

- Brake fluid is crucial for transmitting brake pedal pressure within the braking system. Insufficient fluid levels or aged brake fluid can lead to brake failure, endangering driving safety.

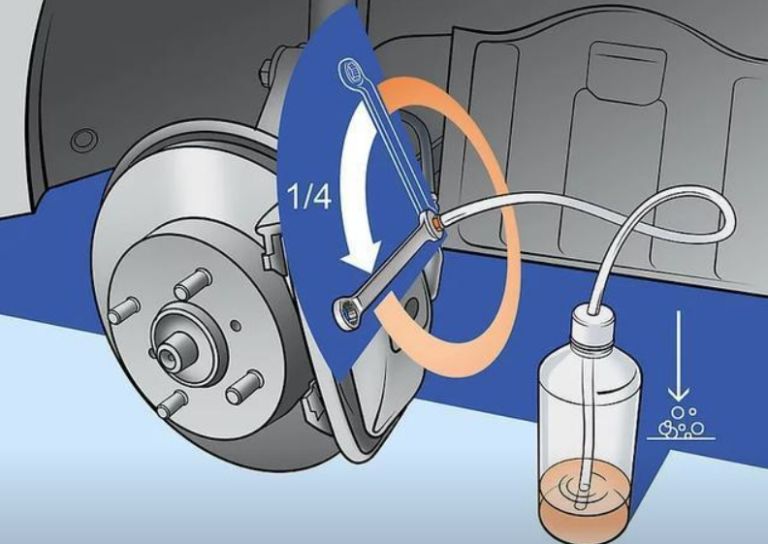

Steps for Replacing Brake Fluid and Bleeding the System

Preparation:

- Ensure the vehicle is stopped and parked on a level surface.

- Prepare new brake fluid, ensuring it meets the vehicle manufacturer’s recommended specifications, such as DOT 4.

Draining the Brake System:

- Use a fluid extractor to remove the old brake fluid from the reservoir, ensuring no old fluid remains in the system.

- Bleed the brake system sequentially from each brake caliper until the new brake fluid completely replaces the old fluid and no air bubbles are present.

Adding New Brake Fluid:

- Add new brake fluid to the reservoir, ensuring the level is within the correct range.

System Check:

- Pump the brake pedal multiple times to ensure the braking system operates normally without abnormal sounds or delays.

Recommended Brake Fluid: For HOWO tractors, DOT 4 brake fluid is recommended. DOT 4 brake fluid has a high boiling point, suitable for maintaining stable braking system performance under high-temperature conditions. It effectively resists brake fluid hygroscopicity, extending the braking system’s service life and providing more reliable braking performance. When replacing brake fluid, always follow the vehicle manufacturer’s recommendations and requirements to ensure braking system safety and reliability.

Ensuring Proper Brake Alignment and Adjustment

Importance of Brake Alignment for Effective Braking

Ensuring the braking system is properly aligned is crucial for vehicle safety and performance. A correctly aligned braking system can stop the vehicle quickly and effectively when needed, significantly reducing the risk of accidents.

Methods for Checking and Adjusting Brake Alignment:

Checking Brake Pad Position:

- Ensure the brake pads (or brake drums) are correctly installed without tilting or misalignment.

Adjusting Brake Position:

- Use a brake adjustment tool or manually adjust the bolts to ensure the clearance between the brake pads and the brake discs or drums meets the manufacturer’s specifications.

Checking Brake Wear:

- Ensure the brake pads wear evenly to avoid unstable braking force or reduced brake pad lifespan due to uneven wear.

Testing Brake Performance:

- After adjustment, perform a road test to confirm the braking performance meets expectations. Pay attention to the brake response time and braking force.

Impact of Improper Brake Alignment:

- Insufficient Braking Force: Misaligned brakes may not provide sufficient braking force, increasing braking distances and accident risk.

- Unstable Braking: Unstable braking may cause the vehicle to shake or vibrate during braking, affecting the driver’s control.

- Premature Brake Wear: Improperly aligned brakes may cause uneven brake pad wear, shortening the braking system’s lifespan and increasing maintenance costs.

Regularly checking and ensuring proper brake alignment is a crucial step in ensuring vehicle safety. Timely adjustments can help improve braking efficiency, reduce accident risk, and protect the safety of the driver and passengers.

Regular Maintenance Schedule and Best Practices

Recommended Brake System Maintenance Schedule:

Regular Inspections and Maintenance:

- It is recommended to perform a comprehensive brake system inspection and maintenance every six months or every 10,000 kilometers. This includes checking the water content in the brake fluid, the wear condition of brake discs and pads, and the overall performance of the braking system.

Brake Fluid Replacement:

- Over time and usage, the performance of brake fluid deteriorates. It is recommended to replace the brake fluid every two years to ensure the efficient operation of the braking system and prevent the risk of brake failure.

Checking Brake Discs and Pads:

- Regularly inspect the thickness and wear condition of brake discs and pads. If the brake pads are severely worn or the brake discs show grooves or wear, they should be replaced promptly to avoid reduced braking performance or brake failure.

Best Practices for Maintaining Brake Components:

- Use High-Quality Parts: Choose high-quality brake discs and pads to ensure the stability and reliability of the braking system.

- Proper Installation and Adjustment: Ensure proper installation and adjustment of brake components, including the contact surfaces between brake pads and discs, and the fastening and connection of brake fluid lines.

- Follow Manufacturer Recommendations: Strictly follow the vehicle manufacturer’s maintenance manual and recommendations, replacing brake components and fluids on time to ensure compliance with vehicle-specific requirements and warranty terms.

Importance of Keeping Maintenance Records:

- Detailed maintenance records help diagnose problems, track component replacement history, and ensure the vehicle’s long-term safety and performance. These records should include maintenance dates, maintenance items, brands of parts and lubricants used, and other detailed information.

Regularly maintaining the braking system and following best practices can significantly enhance vehicle safety and driving experience. Keeping comprehensive and accurate maintenance records is equally important to ensure compliance and safety.

Professional Brake Maintenance Services

Benefits of Professional Brake Maintenance Services:

- Ensure the safety and effectiveness of the vehicle’s braking system. Regular maintenance can help prevent brake failures and accidents, extend the service life of brake components, and increase the driver’s confidence on the road.

Overview of Brake Maintenance Services Provided by HOWO Special Truck Co., Ltd.:

- Our service team is professionally trained and experienced, ensuring your truck’s braking system is in optimal working condition. Services include checking and adjusting brake pads and drums, replacing brake fluid, and adjusting the braking system.

How to Find a Reliable Brake System Maintenance Service Provider:

- Professional Qualifications and Experience: Ensure the service provider has relevant certifications and experience to perform high-quality brake maintenance work.

- Reputation and Reliability: Check customer reviews and feedback to understand the service provider’s reputation and service quality.

- Service Content and Pricing: Compare the service content and pricing of different service providers to choose the one that meets your needs and budget.

- Technical Equipment and Workplace: Modern technical equipment and a clean workplace often reflect the service provider’s professionalism and attention to detail.

- Customer Service and After-Sales Support: Excellent service providers typically offer timely customer service and after-sales support to help address your issues and needs.

Considering the above factors can make it easier to find a reliable brake system maintenance service provider, ensuring your truck’s braking system is safe and reliable on the road.

Conclusion

Regular maintenance of the HOWO tractor’s braking system is crucial. It ensures not only braking performance and safety but also extends the vehicle’s lifespan. It is recommended to follow the manufacturer’s maintenance advice and best practices, such as regularly checking the condition of brake fluid, discs, and pads. To ensure optimal results, regularly inspect the overall condition of the braking system and make adjustments and replacements as needed. For expert advice and support, contact HOWO Special Truck Co., Ltd. to ensure your braking system is always in top condition.

FAQ

It is recommended to check the brake pads every 10,000 to 15,000 kilometers. For long-distance or frequent heavy load driving, the inspection interval should be shortened. Regular checks help ensure the safety and performance of the braking system.

Signs that brake fluid needs replacement include delayed brake response, a spongy brake pedal feel, dirt or impurities in the brake fluid, or the brake system warning light illuminating. Generally, brake fluid should be replaced every two years, but the actual condition should be judged based on vehicle use frequency and fluid quality.

While some simple maintenance tasks, such as checking brake pad thickness, can be done by yourself, it is recommended to seek professional help due to the complexity and safety of the braking system. Professional technicians can ensure a comprehensive inspection and maintenance of the braking system, ensuring driving safety.

HOWO Special Truck Co., Ltd. provides comprehensive brake system maintenance services, including regular inspections, fault diagnosis, parts replacement, and system adjustments. Customers can receive professional support and services through authorized service centers, ensuring the optimal performance of the braking system.